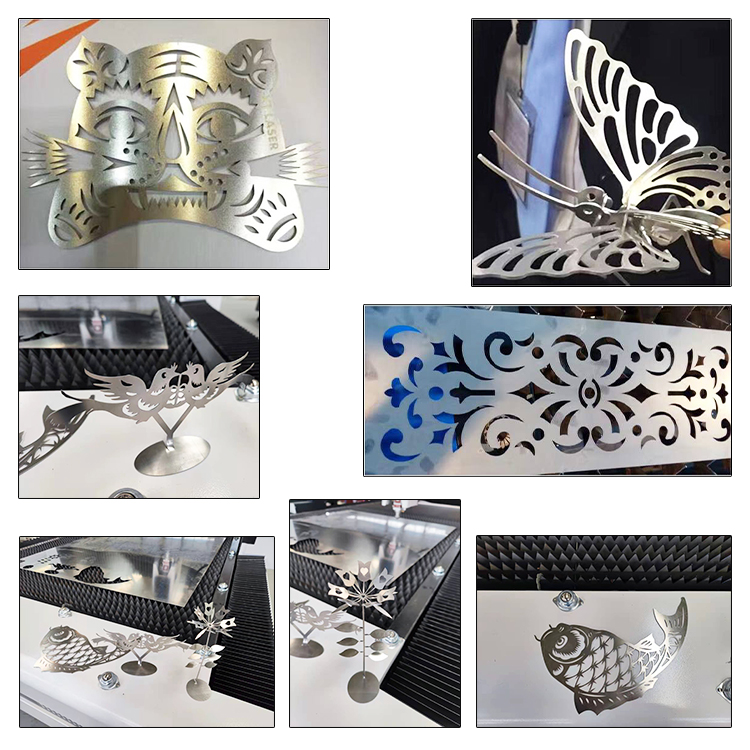

Appication Industries

Widely used in electrical power, automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising signs, car decoration, sheet metal production, lighting hardware, display equipment, precision components, metal products and other industries;

Application materials

Specialized fast speed cutting of a variety of metal plates, pipes (add pipe cutting device), mainly used in stainless steel,

carbon steel, galvanized sheet, electrolytic plate, brass, aluminum, steel, various alloy plate, rare metal and other materials.

| Description and Specifications | |

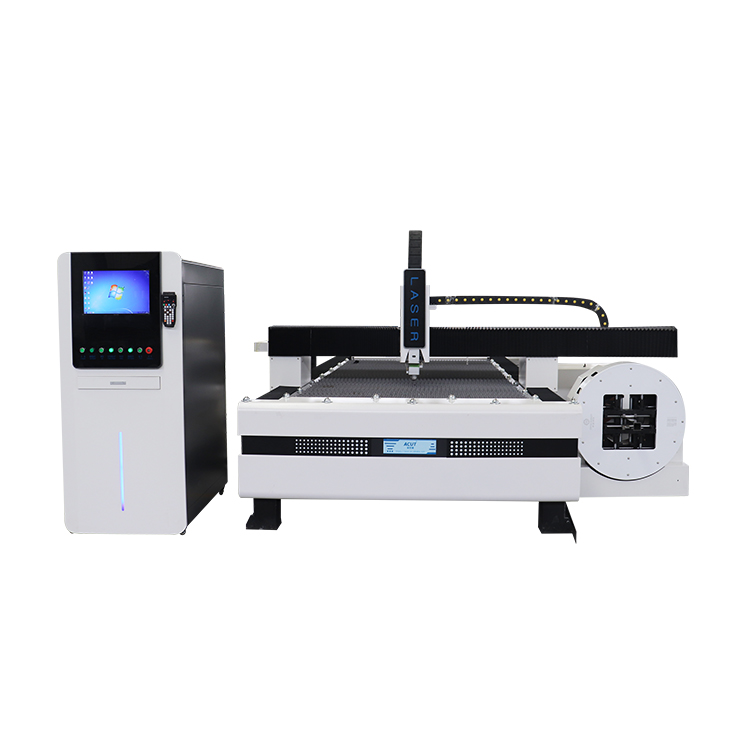

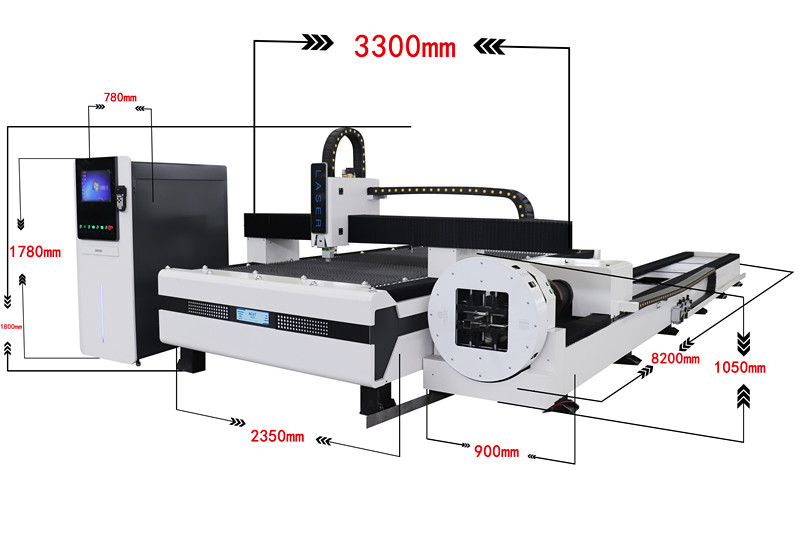

| Model NO. | Metal Sheet Fiber laser cutting machine WITH Rotary |

| work Area | 1500x3000mm |

| laser head | Cypcut |

| Laserkilde | 1000w (1500w 2000w 3000w Optional) |

| Skjæretykkelse | 0.2-10mm(depend on material) |

| Maks skjærehastighet | 40m/min |

| Kontrollsystem | Cypcut |

| Posisjoneringsnøyaktighet | 0.03mm/min |

| Overføring | Taiwan TBI ball screw |

| XY motor and driver | Japanese Panasonic |

| Materiale | Stainless steel/Carbon steel |

| Farge | Valgfri |

| Supported Format | PLT, DST, DXF, BMP, AI, Support AutoCAD, CorelDraw Output Directly |

| Daily working hours | 24 hours without intermission |

| Warranty time | Three years (all accessories) |

| Pakke | wooden box |

| Chinese and English fonts | JA |

| CAD | CAD graphics in various formats can be invoked |

| help function | INCLUDE |

(1) High photo-voltaic conversion rate (above 30%), which helps to save electricity and costs greatly to guarantee the highest production efficiency.

(2) When processing, the laser only consumes electricity and doesn’t need extra gas, bringing the minimum operation and maintenance costs.

(3) Adopting semiconductor modular and redundancy design, without any optical glass in resonant cavity and without start time, so it is in high stability and doesn’t need adjusting and maintaining, which saves the costs and time. In this point, the traditional laser is not comparable.

(4) The output wavelength of fiber laser is 1.06μm, which is a tenth of CO2 wavelength. The output beam is in high quality and power density, so it is easy to be absorbed by metal materials and therefore has great power to cut and weld to make the lowest processing costs.

(5) The laser is transmitted by fiber and there is no complicated reflector or other light guiding system. The optical system is very simple and stable and doesn’t need maintaining.

(6) The laser is output by fiber, which makes the mechanical system design easier and it’s very likely to be connected with robot or multidimensional work platform.

(7) With an optical shutter and by light splitting through fiber cables, the laser source can be used by several machines at the same time.

(8) The fiber laser is small and light and it’s easy to be moved.

Sample:

FAQ

Q1. How to get the most suitable machine and best price?

please tell the material you want to working on ?How to working on it ? Engraving ? Cutting ? Or other ?What’s the MAX size of these material ?( length ? Width ? Thickness ?)

Q2. If we don’t know how to use the machine,can you teach us?

Yes,we will ,if you come to China,we will offer you free training until you can use machine freely.And ifyou are busy ,we will have the special engineer to your country,but you need to bear some fee,like tickets and hotel and meal.

Q3. How about your after-sales service?

we offer you 24 hours service phone,skype or MSN.

Q4. How about your guarantee period?

one year and during the time,if you have any questions ,we will solve it for free.

Q5. How to maintenance the CNC Router?

1. First cut the power when maintain the machine. When check work must open the power, need the professional electrician to do this check work.

2. Repair and replacement the parts, please first confirm the specifications of the technical.

3. Regular clean the cooling system.

4. Should always monitor the voltage and electricity grid of the CNC Router.

5. Prevent the dust into the machine.

Q6. How can i confirm machine?

Dear, in order to recommend the best suitable machine with the best quality and price for you, please kindly contact me with below questions, our professional services will satisfy you!

1. what is you product?

2. what is the material of you product, and the size( length/width/thickness)?

3. what do you want to do on your product, cutting, drilling, milling, evgraving etc.?

4.what is the working area do you want?

5. do you have any other technical requirements? the more the better.if you can provide some pictures of your products,that would be great!

Detaljer

- Bruksområde: LASERKUTTING

- Applicable Material: Metal, Mildsteel Stainless steel

- Tilstand: Ny

- Lasertype: Fiberlaser

- Cutting Area: 1500x3000

- Kuttehastighet: 40m/min

- Støttet grafisk format: AI, BMP, Dst, Dwg, DXF, DXP, LAS, PLT

- Cutting Thickness: 0.2-20mm

- CNC eller ikke: Ja

- Kjølemodus: VANNKJØLING

- Kontrollprogramvare: Cypcut

- Laser Source Merke: Raycus

- Laserhodemerke: Raytools

- Servomotormerke: Yaskawa

- Føringsskinne Merke: HIWIN

- Kontrollsystem Merke: CYPCUT

- Weight (KG): 2800 KG

- Viktige salgsargumenter: Høy nøyaktighet

- Merke for optisk linse: Bølgelengde

- Garanti: 2 år

- Gjeldende bransjer: Hoteller, klesbutikker, byggevarebutikker, produksjonsanlegg, maskinverksteder, mat- og drikkevarefabrikker, gårder, restauranter, hjemmebruk, detaljhandel, matbutikk, trykkerier, bygningsverk, energi- og gruvedrift, mat- og drikkebutikker , Annet, Reklamefirma

- Maskintestrapport: Levert

- Video utgående inspeksjon: Forutsatt

- Garanti på kjernekomponenter: 2 år

- Kjernekomponenter: Trykkbeholder, motor, annet, lager, gir, pumpe, girkasse, motor, PLS

- Driftsmåte: kontinuerlig bølge

- Konfigurasjon: portaltype

- Produkter som håndteres: Plater og rør

- Funksjon: Automatisert lasting

- Product name: 1530 1000w Fiber laser cutting machine

- Working area: 1500x3000mm

- Fiber Lser source: 1000w (1500w 2000w available)

- Laser head: Cypcut

- Cutting materials: Mild steel/ Stainless steel

- Max cutting spped: 40m/min

- Positioning accuracy: 0.03mm/min

- XY travel: 1500x3000mm